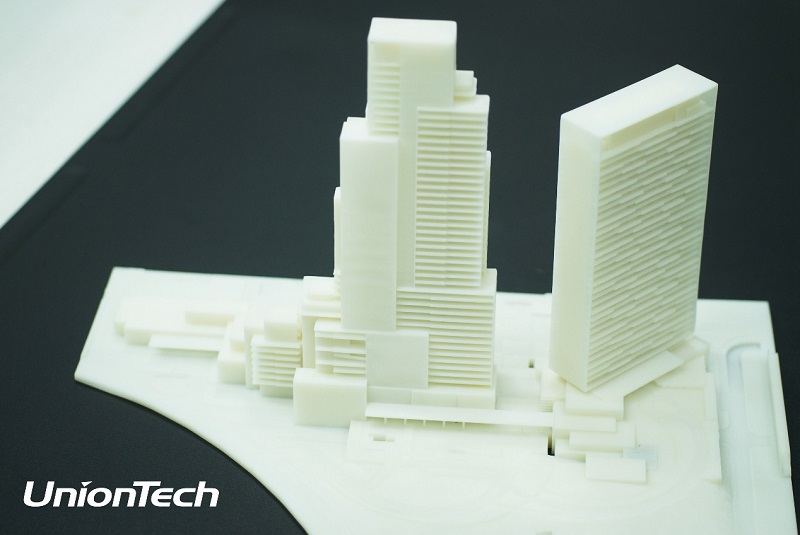

The architectural sand table model represents the architectural art in the form of miniature entities, faithfully expressing the structure of architectural ideas, and transforming the architect’s intention into a concrete image. 3D printing architectural models are fast, low-cost, environmentally friendly, and exquisitely produced, saving a lot of materials, which being more and more accepted by the market.

The architectural model enables the client to have a visualized complete version of the proposed project. However, the process of making traditional building models is very labor-intensive. It is particularly difficult, time-consuming and expensive to accurately reproduce small details. As a result, very critical small details are often discarded, but this is often the presentation of special designs and the key to the customer’s decision-making.

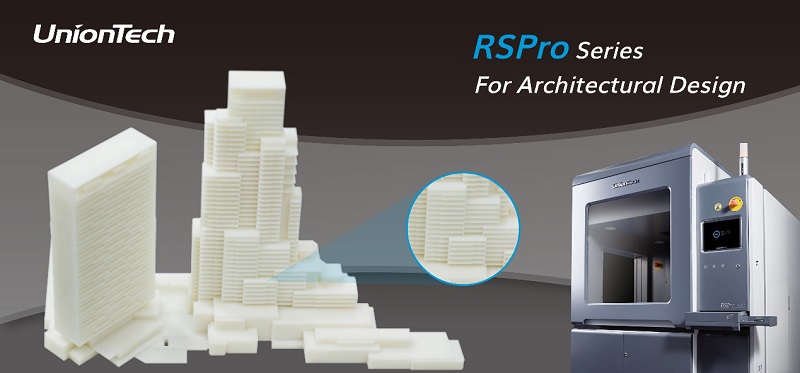

The use of 3D rapid prototyping can reduce the manpower and time required, create detailed and accurate scale models, and effectively convey the unique concept of each design to the client. They are able to replicate fine-scale design elements very accurately in a short period of time, and the production cost is only a small part of the cost of the hand-built model. Models made of sturdy and durable materials, the wall thickness can reach 0.6mm and the intricate details are perfectly presented.

The 3D printing technologies used are FDM, SLA and SLS. SLA technology is especially widely used in the field of architectural modeling.

3D printing building model materials: The materials used for building model mainly include polylactic acid (PLA), ABS resin, light-curable photosensitive resin and thermoplastic (PA nylon powder), etc.

There are three main types of 3D modeling software used in architectural model design: ① Conventional animation software Maya, 3DMax, Rhino; ② Building Information Modeling (BIM) software Revit, Archi CAD, Bentley; ③ Basic drawing software Auto CAD. There is also an open source 3D drawing software SketchUp which is very suitable for architectural model design.

3D data requirements for 3D printing architectural models: In addition to meeting the requirements of 3D printing technology for closed entity documents. Users should also pay attention to the following adjustments of the model:

Before completing the modeling work of the building model, the detailed component size adjustment, model splitting and model assembly design of the model should be carried out according to the performance of the 3D printer and the selected printing materials to ensure the realization of the final use requirements. Due to different 3D printing molding technologies and 3D printing materials, there are minimum wall thickness requirements and subsequent cleaning or support removal requirements. For example, in SLA 3D printing, if the wall thickness is too small, the components are easily damaged during the cleaning process.

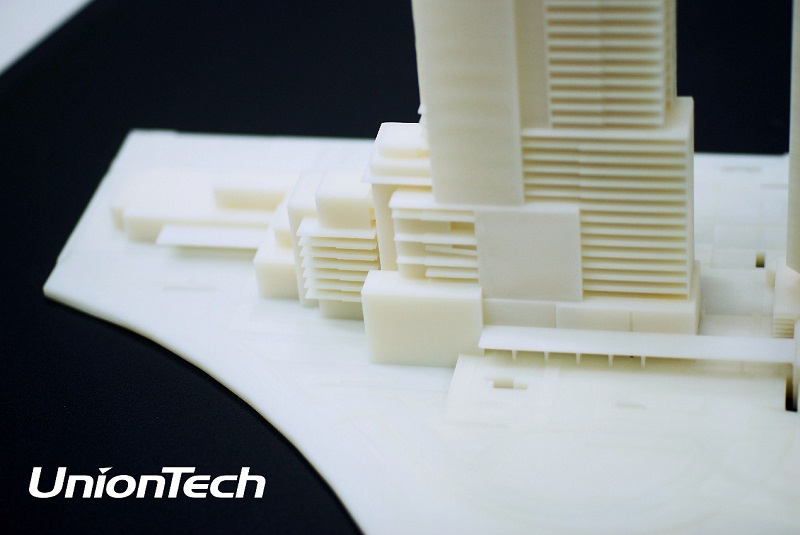

Facade Model Adjustment

Sometimes the final model to be printed exceeds the one-time molding size of the 3D printer, but the model needs to reflect the architectural details. If the user adopts the method of reducing the print size of the model, it is difficult to show the effect in many details. Therefore, according to requirements, the model data needs to be split first, and then printed in blocks, and the final model printing effect could be achieved by splicing. When splitting, try to choose the part with vertical or horizontal lines on the facade, so that the later stitching will not affect the overall performance of the model. Considering the model splicing and preventing deformation, a connecting hook with a certain strength should be designed at the splicing place to ensure the tightness and integrity of the model assembly.

Model Detail Component Processing

When the architectural model is reduced to a scale of tens or even hundreds, exposed details such as pillars, window frames, and railings will become very fragile and cannot be supported. Therefore, some details of the model need to be enlarged and adjusted according to the minimum wall thickness and diameter requirements before it can be printed and cleaned.

Indoor Model Adjustment

The adjustment method of the indoor model component size is basically the same as that of the facade model component, and both need to meet the requirement that the calculated size of the component after being scaled down is greater than the minimum wall thickness of the printer. When adjusting the size of indoor walls, it is necessary to take into account the proportional relationship between different walls, and the mutual ratio between the walls should be as close as possible to the real situation. In order to facilitate the removal of supports, the vertical and horizontal components should be separated before the indoor model is printed, and the splicing method between the vertical and horizontal components in the later period should be designed. The design in which the connecting column at the bottom of the vertical part is inserted into the reserved hole of the horizontal part can be considered. If the later components need to be colored, they should be divided according to the color block and the coloring operation space.